Unlocking the Potential of Bitumen Mixing Machines

In the realm of construction and building projects, efficiency and quality are two paramount factors that can make or break a venture. When it comes to paving roads, preparing asphalt mixtures, and executing various road construction tasks, the utilization of cutting-edge technology like bitumen mixing machines can significantly enhance the overall process and outcome.

Enhanced Precision and Efficiency

Bitumen mixing machines, also known as asphalt mixers, play a crucial role in blending bitumen with other materials to create durable and high-quality asphalt mixtures. These machines are designed to achieve precise mixing ratios and consistency, ensuring that the resulting asphalt mixture meets the required specifications for road construction and repair projects.

Benefits of Using Bitumen Mixing Machines

1. Improved Quality: By utilizing a bitumen mixing machine, construction companies can ensure a higher level of consistency and quality in their asphalt mixtures. This leads to stronger and more durable roads that can withstand various weather conditions.

2. Cost-Effectiveness: Investing in a bitumen mixing machine can prove to be cost-effective in the long run by reducing the need for manual labor and minimizing the risk of errors in the mixing process.

3. Time-Saving: These machines are designed to efficiently blend bitumen with other aggregate materials, saving time and labor during construction projects.

Key Features of Bitumen Mixing Machines

- High Mixing Capacity: Bitumen mixing machines come in a range of sizes and capacities to suit different project requirements, allowing for large-scale asphalt production.

- Advanced Control Systems: Many modern bitumen mixing machines are equipped with sophisticated control systems that enable operators to monitor and adjust the mixing process with precision.

- Durability and Reliability: These machines are built to withstand the demanding conditions of construction sites, ensuring reliable performance throughout the project duration.

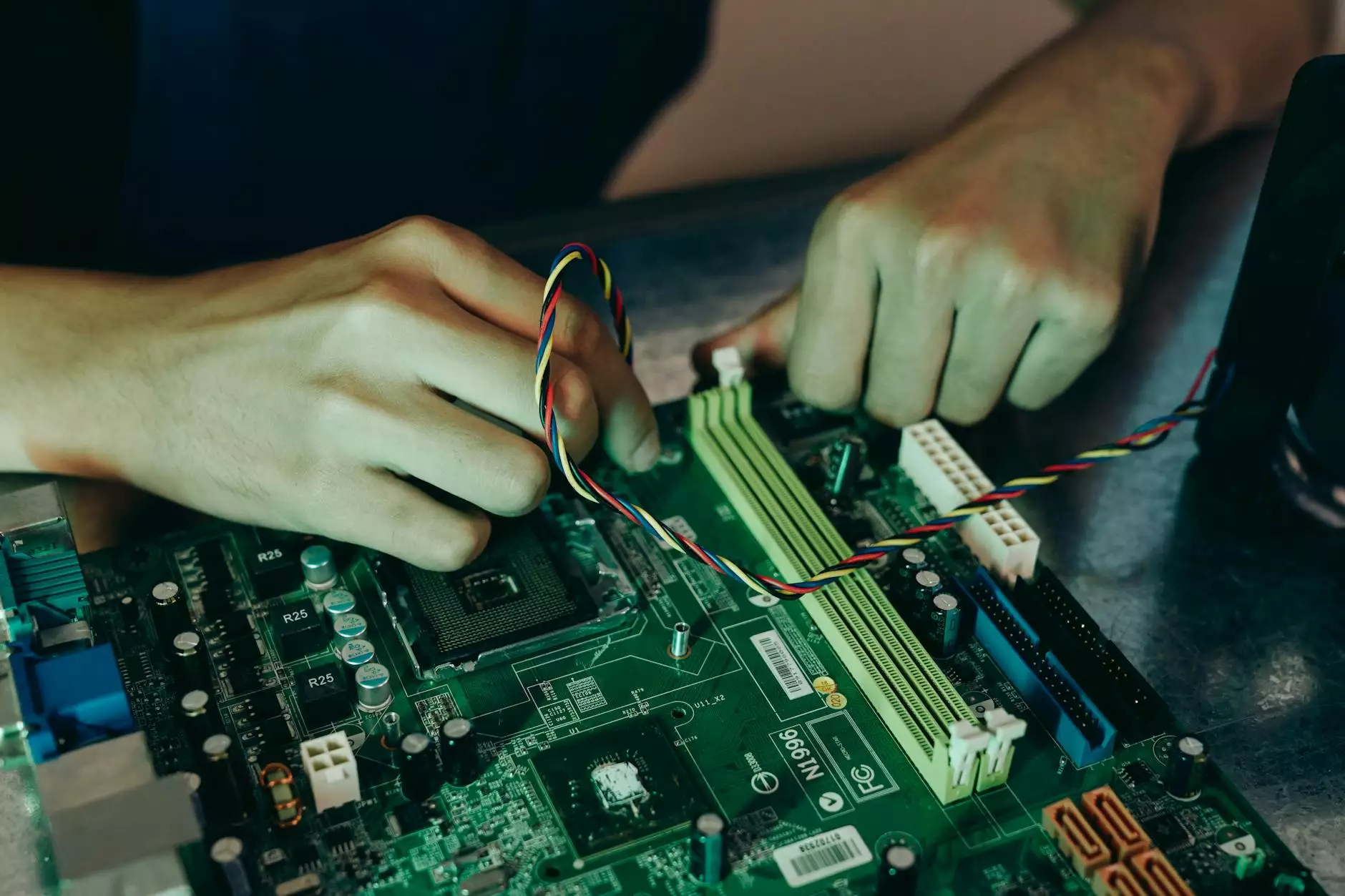

Applications in Electronics and 3D Printing

While the primary application of bitumen mixing machines lies in the construction and infrastructure sector, these versatile machines can also find use in other industries such as electronics and 3D printing. In electronics manufacturing, bitumen mixtures are utilized in the production of circuit boards and other components, where precise blending is crucial for product performance. In the realm of 3D printing, bitumen mixes can be used as a base material for creating intricate designs and prototypes.

Closing Thoughts

As the demands for efficient and sustainable construction practices continue to rise, incorporating advanced technologies like bitumen mixing machines into project workflows can offer a competitive edge to businesses in the industry. By harnessing the precision, efficiency, and quality that these machines bring to the table, construction companies can elevate their capabilities and deliver exceptional results to clients.